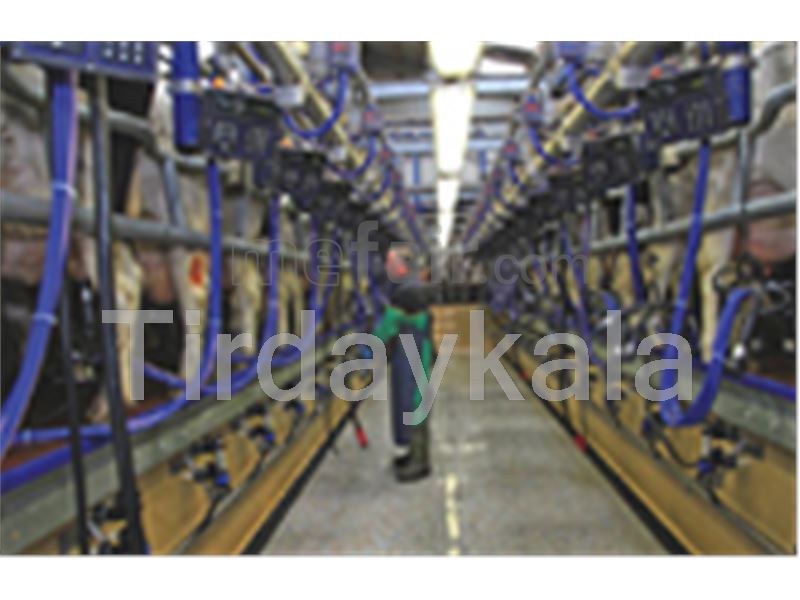

Milking parlor designing

Dr. Doug Reinemann, Professor, Biological Systems Engineering at the University of Wisconsin–Madison, suggests the following ten do’s and don’ts when planning a milking parlor:

1- Know How Much You Can Spend:

A good financial analysis of the farm operation is step one. An unprofitable business cannot afford to invest anything. Saving time does not improve profitability unless there is more profitable use of that time. To be competitive build a ‘reasonably’ sized parlor that fits the budget and avoids putting an extra person in the milking area. Adding more operators never increases the number of animal milked proportionally to the added labor cost.

2- Let the Installer Design the Milking System:

Designing the parlor and milking system to meet all the sanitary and safety regulations is a highly skilled task. Seek the advice of a competent milking equipment installer to work through the planning process with you.

3- Don’t Over Estimate the Value of Old Equipment:

Let your trusted milking equipment installer determine the value of used milking equipment. Most milking equipment is only supported for 10 to 20 years. Replacement parts for older equipment may be unavailable, hard to get, expensive, or all of the above. Maintenance on older equipment can be labor intensive.

4- Get the Building Right:

Buildings generally last a long time and are difficult to remodel. Equipment may last 10 years and is easy to upgrade, as long as the building isn’t the limiting factor. Always compare the cost of renovation versus a new building. It is not always less expensive to remodel, especially if structural modifications and significant concrete removal is necessary. Plan the milking center of your dreams, then scale back. If the budget is limited, spend it on a good building (with a future) and start with a ‘bare-bones’ milking machine.

5- Plan the Building, Stalls, and Holding Area for Good animal Flow:

Lack of good animal movement into and out of the milking parlor is frustrating for both the operator and animals. The milking parlor should be designed to keep the stress level of both the animals and the milkers low. Eliminate turns whenever possible. Where turns are necessary provide adequate space and reduce the number of direction choices animals must make on their own.

6- If You Remodel, Rewire:

Almost every old barn lacks an electrical system that is adequate and safe. Wiring wears out and new wiring methods have been developed. Often the existing wiring cannot handle the capacity of the new electrical equipment added to the parlor.

7- Put in Good Lights:

Plenty of good quality light makes a good work environment. Install energy efficient lights with fixtures designed to operate in a damp location.

8- Consider Energy Saving Technology:

Energy efficiency is a good investment. There is often a 2- to 6-year payback on investments for variable speed drive vacuum pumps, well water pre-cooling of milk, and heat recovery from the refrigeration system.

9- Make Sure Floors Drain Well:

Beware of amateur concrete work! Wet floors make for a slippery, unpleasant work environment. Create mono-slope floors that drain to a gutter rather than multiple slopes to a single drain.

10- Install Good Ventilation:

Ventilation is essential to control the levels of moisture, gases, and pollutants. Cold weather systems provide enough air exchange to provide fresh air, remove moisture, and maintain a comfortable temperature. Warm weather systems do the same, but require a much more rapid air exchange. Be sure to provide adequate controls to allow the system to operate for a time after parlor wash down (and after the operator has left) to remove moisture.