Technical & Economical Evaluation of Using Silicone Rubber RTV Coating for H.V. Substation in Polluted Area

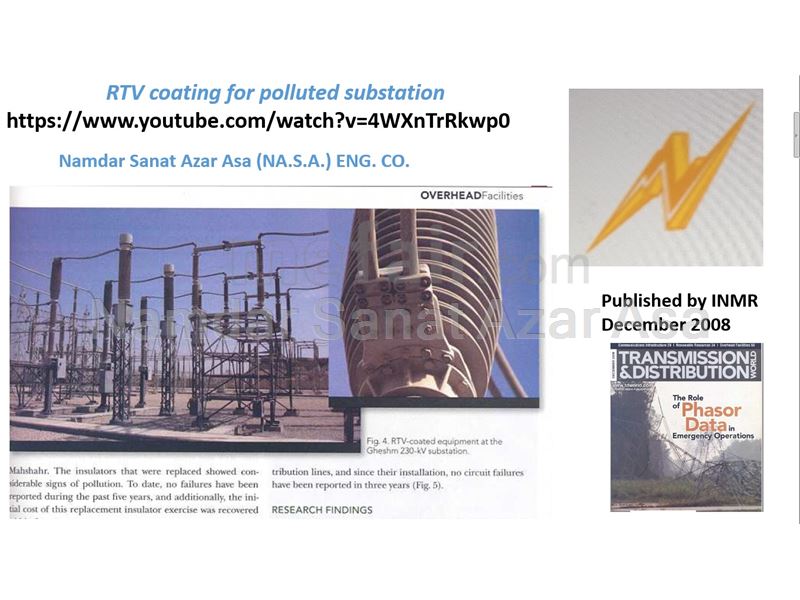

Abstract: High voltage insulators have to be used as insulating supporters in various environments in polluted area. The electrical performance of insulators will be degraded. The polluted insulators will have over withstand voltage, flashover can occur easily when the air becomes wet by humidity or fog, which affects on the reliability of the power systems. In order to define effective counter measures against pollution flashovers there are conventional methods such as periodically water washing and also using silicone grease for insulation. Water washing of insulators which is normally recommended so as to remove the pollution from the insulator surface needs to be done more frequently than other maintenance methods. Though involves some limitation in practice from the technical and economical point of view. Applying of silicon grease on insulators with high cost of performance also is not recommended for use in an environment where high level of NSDD pollution is present. In this paper room temperature vulcanizing (RTV) silicone rubber coating have been presented as a novel approach for improvement of outdoor substation insulators maintenance in polluted area. This method can be used in areas characterized with “Instantaneous pollution” and or with “High or Low level of NSDD” with long life expectancy. Financial analysis shows that this method is also economic and optimal choice. 1-Introduction HV insulation separates voltage levels. Wet polluted deposition forms conductive layer. This layer extends gradually and causes electrical breakage as well as outage. Therefore, appropriate insulation design plays important roll in system reliability improvement and faults reduction in polluted regions. According to utility records, inappropriate insulation constitutes 70 percents of HV lines faults. Respecting to international standards, coastal regions of Persian Gulf and Oman Sea are classified in "very heavy" pollution degree and their hot and humid climate, sea adjacency and salty water provide specific condition. Present insulation design of HV device-lines design in the regions is based on "very heavy" pollution degree standards, but the insulation performance is inefficient. Insulation weaken is the main effect of pollution. Different methods, e.g. periodical washing, are used to reduce these effects in southern regions of Iran. In this paper, traditional maintenance methods in HV substation as well as RTV silicon rubber coating, as a replacement, with their technical-economical considerations are presented and calculations for a typical substation performed.