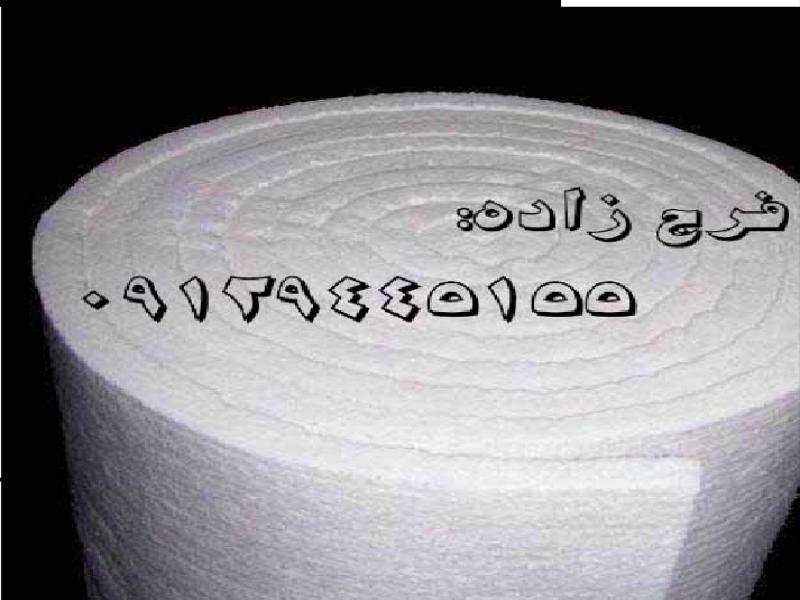

Refractory blanket

Refractory blanket is the same fireproof blanket that has a white color and is made of cotton. Of course, it should be noted that cotton itself is composed of other fibers called ceramic fibers, which have excellent flexibility, low weight, acceptable chemical strength and remarkable mechanical stability.

Product description

Refractory blanket

Refractory blanket is the same fireproof blanket that has a white color and is made of cotton.

Of course, it should be noted that cotton itself is composed of other fibers called ceramic fibers, which have excellent flexibility, low weight, acceptable chemical strength and remarkable mechanical stability; These advantages have made this product admired by industrialists and gathered many supporters around them.

Fans of this refractory material have also produced other products from refractory cotton (composed of ceramic fibers), which include refractory rope, refractory paper, ceramic fiber fabric and refractory board.

Refractory blanket is made of pure refractory cotton that has excellent heat tolerance. This product has a thickness of 50 to 25 mm and its heat tolerance is as follows:

The maximum heat tolerance is in the range of 1260 to 1600 degrees Celsius.

The melting point of this blanket is at a temperature of up to 1760 degrees Celsius.

For high and long use, the temperature has been set from 1177 to 1350 degrees Celsius.

Based on what we have said and studied above, this time we want to tell you the most important benefits of fireproof blankets, which include the following:

It has the ability to dry quickly.

The flexibility is impressive and has a white color.

It has pure compounds.

It has resistance to heat shock and is non-combustible.

Able to control pressures.

Easy handling.

It has significant mechanical strength.

The maximum temperature is up to 1600 degrees Celsius.

It has low thermal conductivity.

Used as sound insulation and is able to absorb sound.

It has special chemical resistance.

Despite these versatile benefits and great fans, in this part of the article we want to address the most prominent applications of refractory blanket, which include the following:

Insulation of boilers and furnaces

Construction of expansion joints

Sealing pipes

Sealing of industrial stoves and dryers

Prepare refractory liners for turbines and cooking wagons

Sealing of annealing furnace

Making brake pads

Sealing of reactors

Thermal and acoustic insulation

Sealing parts in the petrochemical industry

Refractory blanket has a diameter of 3.5 to 2.5 micrometers and can be produced, presented and distributed to dear customers with two densities of 64 and 128.