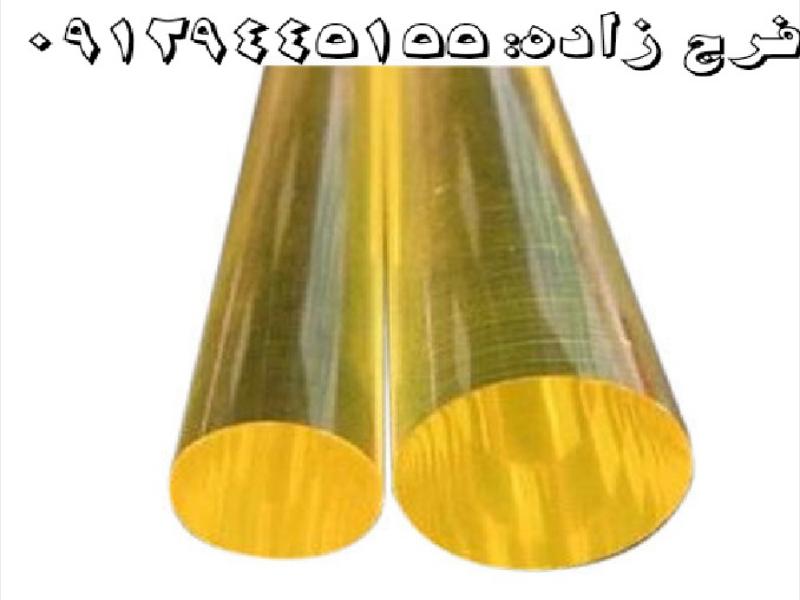

Polyurethane rebar

Polyurethane rebar is a refractory product that is used in many fields. These areas include petrochemicals, power plants, and so on. The product mentioned above is made of polyurethane polymer, which is made by a three-dimensional process.

Product description

Polyurethane rebar

Polyurethane rebar is a refractory product that is used in many fields.

These areas include petrochemicals, power plants, and so on.

The product mentioned above is made of polyurethane polymer, which is made by a three-dimensional process.

Polyurethane polymer is basically made of a large number of monomers, which are a three-dimensional process.

In addition to rebar, polyurethane polymer is also used in the manufacture of sprays and sheets.

This product has electrical and thermal properties and can be used if the parts need insulation.

Polyurethane rebar has acceptable flexibility and is a product that performs thermal insulation and electrical insulation simultaneously.

This rebar is available in lengths of 30 to 100 cm.

In addition to electrical and thermal properties, polyurethane rebar has other properties such as mechanical and chemical strength, which have led to the application of this rebar in various fields.

The thermal tolerance of polyurethane rebar are:

This product can withstand temperatures up to -30 degrees Celsius at low temperatures.

The highest value that this product can tolerate is the amount of heat up to 100 degrees Celsius.

To make more use of this product, a temperature of up to 80 degrees Celsius is recommended.

Polyurethane rebar has a tensile strength of 14 to 63 MPa.

The most prominent advantages of polyurethane rebar are:

It has a reasonable price.

It has good flexibility.

It weighs little.

It has considerable strength.

It is easy to cut and install.

The maximum amount of heat that this product can withstand is up to 100 degrees Celsius.

The lowest amount that this product can tolerate is heat up to -30 degrees Celsius.

It has an excellent mechanical property that is resistant to abrasion and impact.

It can control the pressures on the parts.

It works well in many climates.

It is resistant to dangerous rays.

Some of the applications of this product include the following:

Can be used as a roller on escalators

Manufacture of gaskets, gears and liners

Electrical insulation of components in power plants, etc.

Application in sealing parts in petrochemical field