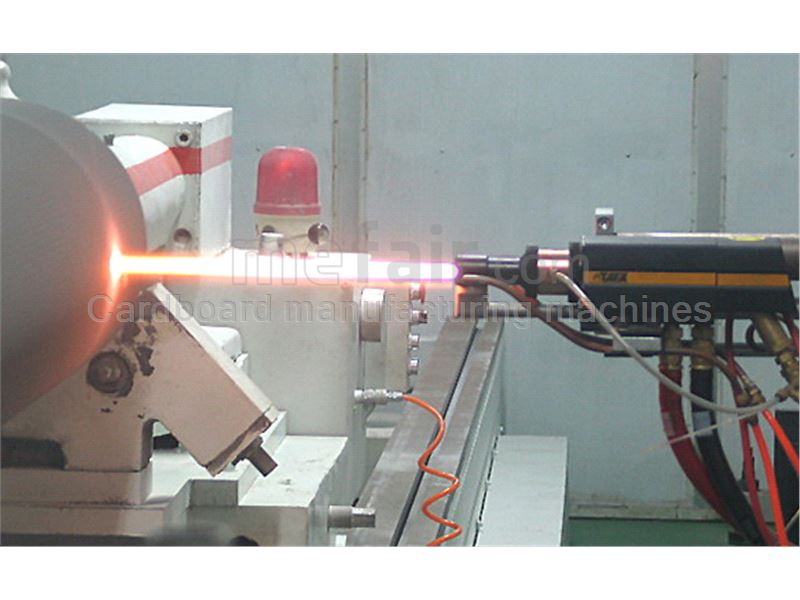

single facer machine for corrugating

Product description

single facer machine for corrugating Advantage

1 Design Speed: 80m/min

2 Effective width: 1400mm-2200mm

3 Corrugated roller:φ280mm

4 Fingerless vacuum suction type single facer, the upper

and lower corrugated roller made of 48 CrMo alloy steel,with

harted treatment,the hardness is above HRC58o-60°The surface is well treated by grind and plated chrome.

5 Upper and lower corrugated roller are unit assemblage,

the whole corrugated rollers group can be move and quick replacement, to change flute type quickly.

6 Glue section are unit assemblage, whole section can be moved by track,save maintenance time.

7Frequency conversion motor as main drive , independent gear box connect with

three gimbal axis, Inverter to make steple

single facer machine for corrugating Feature

1 Oil immersed type lubricating to reduce noise keep running stable, prolong the use life of gear.

2 Adopt Glue width motorized dividing to match the paper width.

Idle running motor for glue applicator roll to avoid glue dry.

Adjustment for gap between glue roller and doctor roller by electric or

manual are optional, Digital read out for the gap between glue roll and doctor roll is optional.

3 Adjustment for corrugated roller,pressure roller,and glue roller by pneumatic system.

4 With preheater for liner paper and steam spray device for medium paper.

5 Bearing for corrugated rollers,and pressure roler adopt high-temperature lubricate grease to keep running smo

| ||||||||||||||||||||||||||||||